Creating a Smooth Wire Feeding Path for MIG Welding

In MIG welding applications, having a smooth wire feeding path is critical. The welding wire must be able to feed easily from the spool on the feeder through the power pin, liner and gun and up to the contact tip to establish the arc. This allows the welding operator to maintain consistent levels of productivity and achieve good weld quality, while also minimizing costly downtime for troubleshooting and potential rework.

However, there are several issues that can disrupt wire feeding. These can cause a host of problems, including an erratic arc, burnbacks (the formation of a weld in or on the contact tip) and birdnesting (a tangle of wire in the drive rolls). For new welding operators who may not be as familiar with the MIG welding process, these problems can be especially frustrating. Fortunately, there are steps to easily prevent problems and create a reliable wire feeding path.

Welding liner length has a big impact on how well the wire will feed through the entire path. Too long of a liner can result in kinking and poor wire feeding, whereas a liner that is too short won’t provide enough support to the wire as it passes through. This can ultimately lead to micro-arcing within the contact tip that causes burnbacks or premature consumable failure. It can also be the cause of an erratic arc and birdnesting.

Trim the liner correctly and use the right system

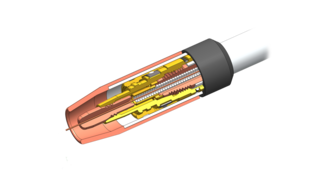

Unfortunately, welding liner trimming issues are common, particularly among less experienced welding operators. To take the guesswork out of trimming a welding gun liner correctly — and achieve a flawless wire-feeding path — consider a system that eliminates the need for measuring the liner for replacement. This system locks the liner in place at the back of the gun, allowing the welding operator to trim it flush with the power pin. The other end of the liner locks at the front of the gun at the contact tip; it is concentrically aligned between the two points, so the liner won’t extend or contract during routine movements.

When using a conventional liner, avoid twisting the gun when trimming the liner and use a liner trim gauge when provided. Liners with an interior profile that imparts less friction on the welding wire as it goes through the liner are a good choice for achieving efficient wire feeding. These have a special coating on them and are coiled out of a larger profile material, which makes the liner stronger and offers smooth feeding.

Use the right contact tip and install correctly

Matching the welding contact tip size to the diameter of wire is another way to maintain a clear wire feeding path. For example, an 0.035-inch wire should be matched to the same diameter contact tip. In some cases, it may be desirable to decrease the contact tip by one size to gain better wire feeding and arc control. Ask a trusted welding consumables manufacturer or welding distributor for recommendations.

Look for wear in the form of keyholing (when the contact tip bore becomes worn and oblong) since this can cause a burnback that prevents the wire from feeding.

Be sure to install the contact tip correctly, tightening it past finger tight to avoid tip overheating, which can hinder wire feeding. Consult the operations manual from the welding contact tip manufacturer for the recommended torque specification.

Choose the right drive rolls and set tension properly

Drive rolls play a significant role in ensuring a MIG welding gun has a smooth wire feeding path.

The size of the drive roll should match the size of the wire being used and the style depends on the wire type. When welding with solid wire, a V-groove drive roll supports good feeding. Flux-cored wires — both gas- and self-shielded — and metal-cored wires work well with V-knurled drive rolls. For aluminum welding, use U-groove drive rolls; aluminum wires are very soft, so this style won’t crush or mar them.

To set the drive roll tension, turn the wire feeder knob to one half turn past slippage. Pull the trigger on the MIG gun, feeding the wire into a gloved hand and slowly curling it. The wire should be able to feed without slipping.

Understand the impact of welding wire on feedability

The quality of welding wire and the type of packaging it is in both affect wire feeding. High-quality wire tends to have a more consistent diameter than low-quality ones, making it easier to feed through the entire system. It also has a consistent cast (the diameter when a length of wire is cut off the spool and placed on a flat surface) and helix (the distance the wire rises from the flat surface), which add to the wire’s feedability. While higher-quality wire may cost more upfront, it can help reduce long-term costs by minimizing the risk of feeding issues.

Wire from large drums typically have a large cast when dispensed from the packaging, so they tend to feed straighter than wires from a spool. If the welding operation’s volume can support a larger drum, this may be a consideration for both wire feeding purposes and for reducing downtime for changeover.

Making the investment

In addition to following best practices to establish a clear wire feeding path — and knowing how to quickly troubleshoot problems — having reliable equipment is important. The upfront investment for a high-quality wire feeder and durable welding consumables can pay off in the long term by reducing issues and the costs associated with wire feeding problems. Less downtime means more focus on producing parts and getting them out to customers.

5 Tips for Robotic Welding Process and Project Planning

5 Tips for Robotic Welding Process and Project Planning

Robotic welding projects can arise in a number of ways — from a smaller shop expanding its capabilities to a large original equipment manufacturer (OEM) awarding new business or even a new company establishing itself within the competitive landscape.

Regardless of the circumstances, it’s critical to implement a well-thought-out and thoroughly researched plan to ensure a successful robotic welding operation. The plan should cover both the details related to the welding process and the specific project at hand. This helps companies meet quality and productivity goals while maintaining their cost margins and achieving profitability.

Being proactive is the key with planning. Doing so helps minimize the opportunity for unforeseen risks that could be detrimental to the welding operation. Some basic tips can help along the way.

Tip No. 1: Ask questions

To determine the desired outcome for a robotic welding operation, it’s important to define the welding process — in terms of how efficient and quick it needs to be — and to consider all details related to the project’s budget. Asking some fundamental questions can help stakeholders define the scope of the process they are using and the project they are undertaking.

- What efficiencies do we need from the welding process?

- How labor-intensive will the process be?

- Is there adequate staff for loading/unloading fixtures?

- What training will staff need to keep the robot welding effectively?

- How many robots do we need? And how hard or long do we want the robots to work?

- What should we consider about the weld cell ergonomics?

- How should the robots be configured?

- What capital is available and how fast do we want our return on investment (ROI) to be?

Answering these questions can help companies as they plan out their project and conduct cost analysis.

Tip No. 2: Set realistic goals

Along with asking questions to set the foundation for solid process and project planning, it’s also important to set realistic goals. These goals should relate to general processes in the robotic weld cell along with desired quality outcomes.

For example, when considering the capabilities of the welding process in a robotic cell, a 75% to 80% efficiency rate may be a realistic goal. No welding process is 100% efficient, so it’s important to account for equipment downtime (planned or unplanned), consumable changeover, welding wire drum changeover and more.

The same holds true for quality goals. Having 100% quality isn’t necessarily true to life since weld defects like porosity can occur, tool center point (TCP) can shift and stampings can become misaligned. Each of these instances is possible (and probable) in an everyday robotic welding operation.

Setting realistic goals allows time for unexpected occurrences once the robotic welding system is at work.

Tip No. 3: Look at the long term

While it may be tempting for companies to look for ways to reduce upfront costs during process and project planning, this doesn’t ensure that the long-term results are always positive. For example, neglecting to consider (and purchase) supplemental equipment, such as reamers (also called nozzle cleaning stations), can lead to greater expenses over the lifetime of a project.

Reamers clean spatter from the welding gun nozzle and gas diffuser to ensure smooth shielding gas flow that in turn supports good weld quality. Reamers are available in analog or ethernet models.

It’s important to consider reamer quality, especially for heavy-duty, higher-volume applications. While reamers with heavy-duty construction generally cost more, they also last much longer than light-duty models. Be sure to size the reamer appropriately for the project because reamers vary in the amount of torque they provide when removing spatter. Heavy-duty reamers provide more torque and have cutter blades that can reach deeper into the nozzle for a more thorough spatter cleaning.

Companies should also determine how much human interaction with the reamer is necessary to keep the welding process at target efficiency levels. For example, implementing a multi-feed anti-spatter sprayer system reduces time and labor for refilling the small sprayer reservoir on the reamer. It can feed multiple reamers from a large drum of anti-spatter solution outside the weld cell.

Tip No. 4: Pay attention to the small details

When it comes to identifying equipment for a robotic welding cell, it may be easy to overlook the importance of robotic MIG guns and consumables. While small in investment compared to a robot, each can have a significant impact on the efficiency of a welding process and the quality of the project.

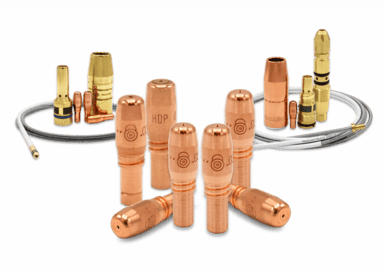

Frequent changeover due to poor-quality MIG welding consumables or ones that aren’t appropriate for the application can add up. Be sure to select those that will be compatible with the heat inputs. Brass nozzles are strong and better able to resist spatter adhesion than copper nozzles. However, brass can be brittle at high temperatures, so they are best for lower-heat applications. Copper nozzles are better for high-heat applications but tend to allow greater spatter adhesion. For pulsed applications, where waveforms can be especially harsh on contact tips, an HDP tip can last longer, reducing the frequency of downtime caused by tip changes. The same holds true for contact tips that offer coarse threads to reduce the risk of cross-threading during replacement. When possible, standardize consumables throughout the entire welding operation to bring greater efficiencies.

Like consumables, the robotic MIG gun selected needs to match the duty cycle of the application to withstand the resistive heat and avoid overheating. The gun should also have an appropriate size of neck for the application to enable access to tooling and the weld joint.

Tip 5: Look for opportunities to optimize

Finding ways to maximize robot uptime is an important part of process and project planning. Robots are expensive, so companies want to be sure that they will get as close to 100% optimization as possible.

Having a high-quality welding wire, like a metal-cored wire, that supports faster travel speeds is one option to help optimize the robotic welding system. Look for wires with a consistent cast and helix to support smooth wire feeding.

Preventive maintenance (PM) programs help ensure that a robotic welding system operates efficiently, avoids unplanned downtime and supports more arc-on time. With a preventive maintenance schedule, companies can proactively check and change welding gun liners and MIG welding consumables during planned downtime, while also assessing the power cable and robot for damage.

It’s also important to plan for the ways that employees can support robot optimization. Training is critical. Properly trained robotic welding supervisors or technicians can be more effective at understanding the process and adjusting equipment as needed. Appropriate training can also help them run the equipment longer and more efficiently.

Putting everything to work

Once a company considers the key tips for process and project planning, they should be sure that everything works. Trials can help flush out unforeseen problems before starting full production and save money by preventing budget overages to fix issues.

After a project has been put into motion, take time for reflection. Revisit all aspects to see what worked and what didn’t. Continuing to learn from projects can help companies achieve future success.

Ways Welding Reamers Support Quality, Productivity and Safety

Ways Welding Reamers Support Quality, Productivity and Safety

A successful robotic welding operation depends on the ability to maintain high levels of quality and productivity, while also keeping costs low. Unplanned downtime associated with consumable or equipment problems jeopardizes these goals. It can also increase the labor needed for troubleshooting and resolving issues.

But above all else, the weld cell needs to be a safe place for welding operators to work and interact with one another and the robotic welding system.

Peripherals, such as welding reamers (also called nozzle cleaning stations), can help companies achieve their goals, while also helping maintain safety.

This article was published in the August issue of The Fabricator. Read the full article here.

New TOUGH GUN TT4A and TT4E Reamers Power Through Spatter to Increase Uptime and Weld Quality

New TOUGH GUN® TT4A and TT4E Reamers Power Through Spatter to Increase Uptime and Weld Quality

WINDSOR, Ontario. (September 14, 2021) — Tregaskiss has introduced its new TOUGH GUN TT4A (analog) and TT4E (ethernet) reamers to maximize uptime and weld quality in robotic welding operations. These nozzle cleaning stations provide superior cleaning performance to power through spatter, improving gas flow and reducing porosity so more time can be spent welding.

Both reamers offer a powerful .95HP motor and 236 pounds of lifting force at 95 psi. Engineered from harder, stronger material, the cutter blades are more resistant to breaking, chipping or cracking.

Adding to the reamers’ performance are several features designed to keep robotic welding operations running for extended periods of time. These include durable valves and cylinders rated for 10M+ cycles and a wire cutter that can run 1M+ cycles without requiring maintenance. The reamers also feature a powerful motor that lasts up to 18M cycles at 80+ psi. A standard motor lubricator supports that performance by extending the life of the motor; it is highly recommended for use in damp and moisture rich environments.

New standard anti-spatter features

Tregaskiss has integrated several new standard features into the TOUGH GUN TT4A and TT4E reamers to help reduce downtime, safety incidents and costly weld defects associated with the use of anti-spatter liquid.

An anti-spatter reservoir with 20-ounce capacity reduces the need for frequent refills to improve productivity, while a low fluid level indicator sends an alert to the PLC/robot when anti-spatter solution is low. This minimizes the risk of running out and helps prevent poor weld quality from lack of shielding gas due to spatter build up. The reservoir includes a tethered cap and easy-clean filter to protect against anti-spatter contamination, which can also lead to weld quality issues. It mounts directly to the reamer frame to increase durability. The reservoir is compatible with the TOUGH GARD® anti-spatter multi-feed system to provide a continuous supply of anti-spatter solution to up to 10 reamers from a 5-gallon pail or 55-gallon drum.

Also standard is a spray containment unit that captures anti-spatter overspray in an enclosed basin, lessening the potential for slip and trip accidents, improving air quality and reducing downtime and cost for cleanup. The weld cell remains dry and clean.

Versatile features and additional options

The TOUGH GUN TT4A and TT4E reamers both feature a four-sided v-block that eliminates the need to purchase new v-blocks when changing nozzle styles, while the TT4E model with ethernet provides greater control and flexibility for remote operation.

Both reamers have external setup switches that allow independent operation of the sprayer, clamp and spindle during manual setup.

Tregaskiss offers additional options for the reamers to further enhance their versatility, including a wire cutter that removes the ball at the end of the welding wire for smoother starts and consistent stickout, along with a reamer stand. A nozzle detect sensor confirms the presence or absence of a nozzle prior to welding to support consistent weld quality and reduce rework. An optional filter/regulator extends motor life by cleaning the air supply to the reamer and keeping debris from entering the motor.

For more information about the TOUGH GUN TT4A and TT4E reamers, visit Tregaskiss.com/robotic-nozzle-cleaning-stations/.

# # #

AccuLock Consumables Save Time and Money in MIG Consumable Changeover

AccuLock™ Consumables Save Time and Money in MIG Consumable Changeover

Estimated reading time: 5 minutes

They may seem like small pieces of a welding operation but when consumables aren’t properly installed or maintained, big problems can result — from poor wire feeding to weld quality issues. Related troubleshooting and rework cause costly downtime and lost productivity.

Consumable changeover can also be a time-consuming part of the welding process, especially if it’s necessary to do it frequently or if less experienced welders install consumables incorrectly.

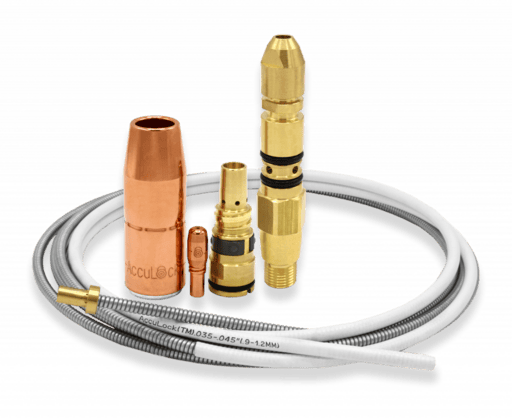

Choosing the right consumables can help reduce or eliminate these hassles. Learn how AccuLock consumables can be used for Bernard® BTB MIG guns and Tregaskiss® fixed automatic and robotic MIG guns to help operations save time and money and improve efficiency.

Although small in size, both AccuLock R and AccuLock S consumables can deliver sizable time- and cost-saving benefits by reducing troubleshooting and downtime in industrial welding applications.

The benefits of AccuLock consumables

AccuLock consumables are designed to address common challenges faced in both semi-automatic and automated MIG welding operations. A switch to AccuLock consumables can help operations:

- Increase consumable life while reducing costs and improving productivity.

- Reduce consumable replacement errors and the time and money spent on troubleshooting, rework and downtime.

- Simplify consumables replacement, improving accuracy and reducing employee training.

The AccuLock consumable family for industrial welding applications includes AccuLock R and AccuLock S systems, two options that are designed to deliver timesaving benefits and optimized performance in automated and semi-automatic welding applications.

Load and lock for increased productivity and throughput

The AccuLock S (Semi-automatic) consumables system features liners designed to resolve issues and errors with liner trimming and installation as well as erratic wire feeding problems. Because AccuLock S liners are locked and concentrically aligned to both the contact tip and the power pin, they offer a flawless wire-feed path and error-proof liner replacement every time. In addition, a steel retaining ring on the diffuser helps keep the threaded nozzle in place during use and cleaning.

The AccuLock R (Robotic) consumables system offers front-loading QUICK LOAD® liners that require less than half the time and effort to replace compared to conventional liners and can be changed from a safe zone in a robotic weld cell. Upgrading to AccuLock HDP contact tips can extend life by 10 times or more in pulsed welding applications. In addition, operations currently using TOUGH LOCK® consumables in robotic and fixed automatic MIG guns can easily upgrade to AccuLock R consumables without affecting TCP or requiring programming changes.

Choose according to your needs

When deciding between the two types of AccuLock consumables for industrial welding applications, there are several key factors to consider. It’s important to think about the type of welding being done in the operation and what current issues or challenges need addressing.

AccuLock S consumables are best suited for operations with the following issues or characteristics:

- Primarily focused on semi-automatic welding with little to no automation.

- Dealing with decreased productivity due to liner installation errors, burnbacks, bird-nesting and erratic arc.

- Wanting to reduce the time and costs of troubleshooting, downtime and rework.

AccuLock R consumables are best suited for operations with the following issues or characteristics:

- Primarily focused on robotic or fixed automatic welding with few semi-automatic guns.

- Having a complicated and costly consumables inventory that may be the root cause of frequent consumable replacement errors.

- Experiencing issues with contact tip cross-threading and want increased tip life.

Choosing between AccuLock S and AccuLock R on semi-automatic MIG guns

Customers who are currently using TOUGH LOCK consumables on Bernard BTB MIG guns can upgrade their guns with either AccuLock S or AccuLock R consumables. Although AccuLock S consumables offer many benefits specific to semi-automatic welding applications, in some cases it can make more sense for these welding guns to be upgraded to AccuLock R consumables instead. For example, if a complex inventory of MIG gun consumables is the primary root cause of high carrying costs and consumable replacement errors in a given facility, AccuLock R consumables may offer a better ROI.

Switching existing Bernard BTB MIG guns to AccuLock R consumables is an easy change to make, requiring only an AccuLock R diffuser and an AccuLock contact tip — with no need to switch the liner, power pin, power pin cap or nozzle.

Successful welding operations simplify inventory

Both AccuLock S and AccuLock R systems share a common contact tip to simplify inventory management for facilities that choose to use both. AccuLock contact tips last longer due to increased mass and being buried within the diffuser, away from the heat of the weld. Coarse threads work in tandem with a long contact tip tail to concentrically align the tip within the diffuser prior to thread engagement, ensuring quick, accurate replacement without cross-threading.

Getting the most out of MIG gun consumables

AccuLock S consumables solve many of the issues that can be traced to MIG gun liners that have been trimmed to an incorrect length or that pull out of position inside the MIG gun, creating gaps along the wire feed path. They are a good fit in most semi-automatic applications.

In fleets with a lot of automated welding, AccuLock R consumables can extend contact tip lifespan (especially in pulsed welding applications), eliminate contact tip cross-threading issues, alleviate excessive downtime for consumables replacement and limit safety issues related to climbing up to access robots or wire feeders for gun liner changes.

Although small in size, both AccuLock R and AccuLock S consumables can deliver sizable time- and cost-saving benefits by reducing troubleshooting and downtime in industrial welding applications.

Improve Productivity by Preventing 5 Common MIG Welding Problems

Improve Productivity by Preventing 5 Common MIG Welding Problems

Downtime and rework can be costly for manufacturing operations. The last thing any production team wants to do is the same work twice. If you add to that any time spent troubleshooting issues in the weld cell — the lost production time can start to accumulate quickly.

There are several steps operations can take to reduce the time lost to these common issues in MIG welding — and many of them start during weld setup and selection of consumables. Read on to learn more about five common causes of lost productivity in the weld cell and how to prevent them.

Cause 1: Poor fit-up or weld prep

Before welding even starts, pay attention to proper fit-up and joint design, as well as base material preparation and cleaning. Good fit-up means avoiding large or inconsistent gaps between the parts. Choosing the right wire size and gas mixture and matching those in advance can help optimize performance and provide proper gap filling capabilities.

Certain welding wires, such as metal-cored wires, are usable on less-prepped base material by offering the ability to weld through mill scale or other surface impurities. They also offer good gap bridging. If operations are often getting parts that aren’t thoroughly cleaned, it may be worth testing a metal-cored wire. Otherwise, changes to the weld prep stage of the operation may be necessary to achieve better material condition prior to welding.

Cause 2: Incorrect parameters or system setup

Using the wrong parameters or setting the wire feeder up incorrectly are common causes of lost productivity. Having the wrong settings can greatly affect the weld, sometimes without the operator even realizing the impact that a setting change can make. It’s important to have a thorough understanding of the wire feeder and all of its functions to set it up for optimal performance.

When properly set up, there should be very few issues with the performance of the MIG welding gun. However, if the system is set up incorrectly or there is a poor weld circuit, it can lead to contact tip failure, since the contact tip is the smallest fuse in the weld circuit. This can result in money wasted on frequent contact tip changeover.

Cause 3: Improper liner installation

MIG gun liners can wear out over time and must be changed periodically, like other consumables. However, replacement liners are often longer than necessary and must be precisely trimmed according to the style and length of the gun. If a liner is cut too short, it can result in issues like burnback, an erratic arc and wire chatter. When liners are cut too long, it can cause the wire to weave and curve as it feeds through the gun.

With either too-long or too-short liners, the result is often poor wire feeding and downtime spent troubleshooting these problems. Maintenance and troubleshooting for liner issues can be costly, resulting in multiple hours per week lost for an operation.

The more that liner movement within the gun can be minimized, the better your wire feedability will be. To avoid the guesswork and hassle, look for a solution that makes liner installation and trimming easier. The Bernard® AccuLock™ S consumable system affixes the liner at both ends of the gun, so welders are assured the liner won’t pull back or push into the contact tip, allowing for smooth, uninterrupted delivery of the wire to the weld pool.

It’s also important to occasionally check to make sure the liner is clear and not blocked by debris or buildup.

Cause 4: Loose connections or neglected maintenance

When MIG welding consumables aren’t properly installed and maintained, it can result in wire feeding issues and weld quality problems that lead to lost time for troubleshooting.

For example, a loose connection in the weld circuit means you’re not getting the power you expect from the power source. In that case, the operator may keep adjusting the parameters, causing an increase in resistance that leads to shortened consumable life. These issues tend to show up first in the contact tip. This is often the first thing the operator changes if they think they have a problem with their MIG gun. Changing the contact tip — even when the real source of the problem is a loose connection or improper setup in the circuit — drives up consumable costs and wastes time.

Be sure to periodically check and tighten all connections and cables. Tight connections help optimize performance and reduce the chance of issues occurring in the system.

Cause 5: Cutting corners with contact tips

Another cause of lost productivity is using low-quality contact tips. Some contact tips are designed for ease of use and high performance. They provide better arc starts, less spatter, more consistent welds and longer life.

With Bernard AccuLock S consumables, 60% of the contact tip is buried in the gas diffuser to protect it from heat damage. As the shielding gas flows through the gun, it cools the contact tip tail inside the gas diffuser. This helps reduce heat and wear. This also differs from traditional tips that screw onto the gas diffuser with little to no portion of the tip exposed directly to the shielding gas as it exits the diffuser to the arc. The tapered design of the consumables tightly locks the conductive parts together to minimize electrical resistance and further reduce heat buildup. The contact tips also feature coarse threads, making them less likely to become cross-threaded.

Troubleshooting common welding problems

Common problems in the weld cell — from poor fit-up or wire feeding issues to using the wrong consumables for the job — can cost the operation significant time and money. Addressing the causes of lost productivity often starts with proper weld prep and setup, as well as making sure the chosen consumables are right for the application. Optimizing setup and efficiency in the weld circuit makes troubleshooting that much faster when issues do arise.

Implementing a Robotic Welding System: 5 Common Questions Answered

Implementing a Robotic Welding System: 5 Common Questions Answered

Estimated reading time: 7 minutes

Many manufacturing operations want to improve productivity and weld quality. Robotic welding can often help achieve these goals. But success with a welding robot doesn’t happen by chance. It takes a lot of upfront planning to help minimize the time and money you need later to make improvements or fix issues.

Before getting started, consider how these common questions could impact the way you establish a repeatable and consistent robotic welding operation — and how you can get the most out of it.

A: The filler metal used in a robotic welding system plays a critical role, as it can affect productivity, weld quality and overall costs. When you choose a wire for robotic welding applications, consider two things: the type and the thickness of the material being welded.

Across various industries, solid wire has been the standard for robotic welding. However, metal-cored wire may offer better productivity and higher quality benefits, especially for manufacturers of heavy equipment, automotive exhaust, chassis and wheels. Metal-cored wire not only allows for faster travel speeds and higher deposition rates, but it also more effectively controls spatter levels to reduce post-weld cleanup. Last, it offers improved welding through mill scale, which helps eliminate pre-weld grinding.

When in doubt, you can get suggestions from experienced welding equipment and filler metal manufacturers to help you match a welding wire to your process needs.

A: Performance in a robotic weld cell is significantly affected by your choice of robotic welding gun and consumables, including the nozzle, contact tip and liner. The right combination of gun and consumables can reduce unplanned downtime, increase lifespan and improve overall equipment effectiveness (OEE) in your weld cell.

There are three types of robotic guns to choose from, depending on your duty cycle and amperage ratings: air-cooled, water-cooled and hybrid. It’s possible for air-cooled guns to reach ratings of 350 to 385 amps at 100% duty cycle with mixed gases. Guns with this rating are well-suited for a variety of applications and help eliminate the need for water-cooled guns, which can be more complex and expensive to maintain. However, hybrid air/water-cooled designs incorporate water cooling on the front of the neck with an air-cooled cable. This design is good for applications with borderline air-cooled duty cycles that experience a higher frequency of consumable changeover. The hybrid gun is the best option to provide an additional rating boost while effectively cooling the consumables, leading to longer lifespans.

Robotic welding systems typically operate at higher duty cycles (compared to semi-automatic welding) and may use transfer modes that can be harsh on consumables. Consider using heavy-duty copper or chrome zirconium contact tips or high-quality tips designed specifically for pulsed welding. Chrome zirconium contact tips resist physical wear (or the keyholing effect) better than copper tips and are ideal for applications with long welds. Make sure to undersize the contact tip from the wire size when using 500-pound-plus wire drums to help ensure consistent wire contact with the tip due to the wire cast. Keep the tips on par with the wire size in small wire packaging.

Nozzle material also plays a factor in the application. Brass nozzles are stronger and have a lower spatter adhesion compared with copper, but brass is more brittle at higher temperatures. In short, brass handles spatter best while copper best handles higher heat.

Choosing a quality liner pays dividends in reducing your unplanned downtime. The majority of time, burnback in contact tips is a direct result of poor wire feeding or a liner cut too short. An accurately trimmed, quality liner will help to consistently improve wire feeding by reducing drag. The result is longer-lasting contact tips and improved robot uptime.

![]()

A: Several factors, such as material type, wire size and material thickness, influence the proper weld settings for an application. Some welding power sources have the ability to suggest recommended parameters based on the operator’s input for the application.

When a machine doesn’t have this technology, finding the correct parameters can involve some trial and error on your part to dial in heat and penetration. Consult with the robot manufacturer, welding power source manufacturer or system integrator. These partners can offer expertise and assist in choosing and testing specific materials to establish the proper weld parameters.

A: Establishing an accurate tool center point provides consistency and repeatability across parts and is vital for your system to maintain quality welds.

You can set your own standards for the acceptable amount of TCP drift based on the application and type of welds being made. To set the tolerance of TCP variation, an acceptable starting point can be half of the thickness of the wire diameter. Also keep in mind that your TCP correlates with your contact tip wear — the more key-holed a tip, the more off location your TCP will be.

Touch-sensing features that monitor TCP and track any shifts from the original setting are available on many robotic systems today. If a gun is out of acceptable TCP range, you can remove the neck and recalibrate it to the original specifications with a neck-straightening fixture. TCP can also be automatically adjusted internally by the robot on some systems.

It’s a good idea to schedule regular TCP checks. For example, it can be done every weld cycle, at the end of every shift or when the gun goes through a reamer cycle. The frequency of TCP checks is a matter of your priority preference. While it can be time-consuming to check after every shift, in the long run it can save money by avoiding rework if problems are caught early.

![]()

A: Much like programming the weld settings, programming the robot path may also involve some trial and error. When you initially program the robot’s path, think about four factors: the application, the material type, the welding process you are using and the gap size being filled. The travel angle — and whether it’s a push or pull weld — will impact the weld quality and aesthetic. Dialing in the correct path to achieve your desired results can take time.

Having the robot move to perch points or ready-to-enter points once the home positions are set helps to keep the robot safely away from potential collision areas. It also allows the system to move with air-cut moves to and from these points quickly and effectively.

When you program the robot to move to a weld, it’s common to set the approach point just above the weld start location. The robot should approach the start location at a slower and safer speed before it strikes an arc. This approach position provides a good lead-in and typically does not require adjustment unless the weld is relocated. Some robotic systems have technology that assists in setting the initial robot path.

The robot’s welding location can play a role in premature gun failures. Heavy articulation in the gun or an excess of +/-90 degrees, especially during welding, can cause accelerated cable failures. Minimizing your robot’s axis five and six during welding can help extend gun life by reducing wear.

Tips for robotic weld cells

Many variables, including proper cable and consumables selection and TCP control, play an important role in weld quality and gaining successful results with a robotic welding system. Establishing a thorough plan before implementation and continuing to monitor key issues can help you optimize your OEE so you can get the most out of your investment.

Manufacturer Cuts $45,000 of Costs With New MIG Welding Guns and Consumables

Manufacturer Cuts $45,000 of Costs With New MIG Welding Guns and Consumables

General Kinematics — a premier manufacturer of vibrating equipment for processing bulk materials — has been providing consistent, on-time and innovative solutions to its customers for more than 60 years. The company prides itself on offering rugged, cutting-edge equipment to manage difficult-to-process materials across the mining, resource recovery, bulk processing and foundry industries.

A reputation for design leadership and creating tailored technical advancements sets the company apart from the competition, as does its commitment to providing excellent service.

This 200-person, Crystal Lake, Ilinois-based company doesn’t have time for slowdowns, especially in the welding operation. In recent years though, General Kinematics noticed exactly that. It was experiencing repeated MIG gun breakdowns and excessive contact tip consumption that slowed production.

“Between costs and repairs and lost labor from the welders having issues that stopped their progress, we estimated around $45,000 a year in costs from these issues,” said Jason Jerik, plant manager at General Kinematics.

That’s when Jon Strug, the company’s maintenance tech, approached their welding distributor, Steve Schuette of Weldstar in Aurora, Illinois, for a solution. Schuette recommended a trial of Bernard BTB air-cooled MIG guns with AccuLock™ S consumables.

Considering the change

Problems with the water-cooled MIG welding guns at General Kinematics were at the heart of its need for a new solution.

“The guns were definitely our main issue with maintenance for Jon,” said Joel Jacobson, director of manufacturing. “It was tough to keep up to the demands of the hoses breaking, the wires breaking internally in the guns, tips burning out, liners and such.”

Jerik added, “The last time we calculated from a dollar standpoint it translated to about five to seven hours a week in lost time just with liner issues. It was that frequent.”

The team, along with Schuette, took a slow and thorough approach to testing the Bernard air-cooled BTB MIG welding guns and consumables, making sure that the products performed as expected. They worked first with some sample guns in standard sizes and leads and had different welders try them for a week each.

“We would test a week with one fitter, a week with one welder, and then we’d move them around to see what kind of acceptance we would get with them,” said Jacobson.

General Kinematics welds a variety of materials — from A-36 steel to AR-500 plate — in thickness up to eight inches and on a variety of joints. Welding operators also weld both large and small weldments and use different welding wire diameters. The guns and consumables needed to be versatile enough to manage these jobs and produce the quality needed to adhere to the American Welding Society (AWS) D.1.1 Structural Welding – Steel code. They also had to be the right equipment for the company’s welding operators.

Jacobson and Jerik regularly met with the welding operators to request feedback during the trial.

According to Jerik, welding operators saw noticeably less consumable consumption. However, they wanted to change the angle on the neck of guns to gain better access to some difficult joint configurations. They worked back and forth with Bernard to determine a different angle of the neck that suited their needs.

“We wanted to do a thorough run of testing and vetting out to decide ‘Is this the right product for us? Are we going to get that buy-in from our welding operators?’” he said.

Ensuring that welding operators liked the MIG welding guns and consumables was a critical part of the testing General Kinematics conducted. The company has a culture of empowerment and wanted its welding operators to be heard and to contribute their opinions.

“We think it’s important to get our welders involved early in the process,” said Jacobson. “Not everyone likes change, but getting them involved in testing up front can help show the long-term benefits.”

“I’m huge on that,” Jerik added. “I’d rather not force and push a change onto a team. I’d

rather them accept it and make it their own.”

After eight months of testing, processing feedback and making adjustments, General Kinematics made the decision to convert to the Bernard BTB air-cooled MIG guns and AccuLock S consumables.

The benefit of the investment

General Kinematics invested in 400-amp BTB air-cooled MIG guns for its 40 welding operators, as well as several 450-amp Bernard water-cooled guns — all with the same AccuLock S consumables. Bernard built the company a special neck for its water-cooled guns to provide better ergonomic access to typical weld joints, and these guns are the first of their kind ever to be configured with the AccuLock S consumables.

So, what finally sold General Kinematics on the Bernard products? In short, durability and performance.

The reduction in gun maintenance was key. Strug no longer has to contend with leaking water-cooled guns or liner issues that need fixing — and the new guns and consumables are less frustrating for the welding operators, who can now spend more time being productive.

“We have a whole lot fewer repairs. Before it was constantly, every month, seven guns I had to send out to get repaired or I had to repair them myself,” said Strug. “It’s a huge difference in quality — night and day.”

This durability and performance result from a combination of the rugged construction of the BTB air-cooled MIG guns — which were configured according to the handle, neck, trigger and cables the company needed — and the liner that is part of the AccuLock S consumables system.

Bernard designed the liner in the system for error-proof replacement by eliminating the need to measure it prior to installation. Instead of the liner loading from the back, like many competitive guns, the AccuLock S liner loads in the neck at the front of the gun and then locks in place so it can be trimmed flush with the power pin. This prevents the liner from being trimmed too short or too long.

“I like the liners,” said Strug. “They last a lot longer and I definitely like the quality of them.”

According to Jacobson, another selling point was that AccuLock contact tips run significantly cooler than the company’s previous ones so there is less consumption and downtime for changeover.

That’s due to the design of the tip and gas diffuser. Sixty percent of the welding contact tip is buried in the gas diffuser, which protects it from heat damage, and the shielding gas also cools the contact tip tail as it flows through the gun. AccuLock consumables have a tapered design that locks the tip, gas diffuser and nozzle tightly together to further reduce electrical resistance and lower heat buildup.

Jacobson likes the ability to reduce costs by having equipment that lasts longer. And both the air- and water-cooled MIG welding guns use the same AccuLock S consumables, which helps reduce inventory management.

The welding operators like that the guns and consumables run cooler and help reduce spatter, so there is less cleanup.

The long-term benefits

For General Kinematics, making the change to the Bernard BTB guns and AccuLock S consumables is just another way the company commits itself to quality. But there has been more to the conversion than that.

General Kinematics was able to gain a return on investment in approximately 12 to 14 months. And while there are still labor and equipment costs for gun and consumable maintenance, the conversion has eliminated the $45,000 in extra spending to address previous issues with the water-cooled guns.

The products have also helped its welding operators achieve approximately 10% more productivity by eliminating downtime. That’s important to the welding operators and to Jerik.

“When it comes down to it, do these products make their job easier? Do they make them more productive?”

The answer to both is yes.