NEW PRODUCT —

Tregaskiss Power Pin for Fronius VR1500 Wire Feeders

July 1, 2009

Tregaskiss has designed a power pin (part #214-41) that can be used in place of the actual Fronius® Power Pin for the VR15000 wire feeder.

This new power pin is compatible with Tregaskiss TOUGH GUN® robotic and automatic MIG guns and Bernard® T-Gun™ semi-automatic MIG guns (formerly Tregaskiss TOUGH GUN semi-automatic MIG guns).

- Threads into all Tregaskiss unicables (except Euro) and is the standard Fronius power pin for TOUGH GUN ThruArm™ series robotic MIG guns

- Compatible with Motoman® unicables on teh EA/SSA Series robots

- Designed specifically for use with QUICK LOAD® liners

A liner cap adaptor (part #214-41-3) is also available for upgrading existing Fronius power pins to the QUICK LOAD liner system.

QUICK LOAD™ Liner System by replacing it with the

Tregaskiss Liner Cap (part #214-41-3).

Fronius wire feeders can come with several types of connections. The following chart indicates the recommended Tregaskiss power pin solution for each:

| Fronius® Feeder Connection Type | Tregaskiss Part Number |

|---|---|

| Fronius “North America” Power Pin | 214-17 |

| Tweco® #4 | 214 |

| Euro Connection | Euro |

| Fronius Power Pin #4.045.848.638 for VR1500 Feeder | 214-41 |

| Fronius F++ | Not Available |

September 29, 2009 Tregaskiss has made a change to its quick-connect blocks 417, 417-50, 417-60 and 417-63. The brass fitting on the end of the gas hose (as shown in the 417-63 Miller® quick-connect block image to the right) has been removed from these quick-connect blocks.

November 26, 2009 Customers may notice that some Tregaskiss® parts and consumables are arriving in different bags. We transitioned from the white bag design branded with the TOUGH GUN® name to a black bag design with the Tregaskiss brand name. In addition to changing the branding and color of the bags, the overall usability has also been improved. The new Tregaskiss black bags offer a clear window on the printed side of the bag to make visual product identification easier. To increase the hanging capacity of the bags, we’ve added a second hanging hole on our larger bags and a new double-sealed header on all bag sizes. We have also changed all the hanging holes from circular to sombrero shape for compatibility with a wider variety of hook sizes and shapes. The roll marks pressed into our genuine parts and consumables have also migrated from a plain font “TOUGH GUN” to the script-style Tregaskiss logo. This will help customers more easily distinguish genuine Tregaskiss consumables from generic impostors. The primary reason for these packaging and roll mark changes is to more accurately market our Tregaskiss consumable platform under the Tregaskiss trademark. Marketing these parts and consumables under the TOUGH GUN name could be misinterpreted to mean that these items can only be used on TOUGH GUN products. However, Tregaskiss parts and consumables have actually been designed to maximize compatibility with Tregaskiss TOUGH GUN robotic and automatic MIG guns, Bernard® T-Gun™ semi-automatic MIG guns (formerly Tregaskiss TOUGH GUN semi-automatic MIG guns), and Bernard TGX® series MIG guns (formerly Tregaskiss TGX series MIG guns).

July 14, 2010 Tregaskiss has expanded its QUICK LOAD® liner offering ot include three new wire sizes for 0.030″, 1/16″ to 5/64″, and 0.078″ to 3/32″ wires. QUICK LOAD liners consist of a two-piece system that requires less than half the time and effort for replacement compared to conventional MIG gun liners, and they also ease routine maintenance. The welding operator simply installs the retainer in the power pin on the first use. During subsequent liner replacements, the QUICK LOAD liner feeds through the front of the MIG gun, which can remain attached to the wire feeder during liner replacement. The welding operator needs only to remove the front-end consumables (nozzle, retaining head and contact tip) and slide the liner over the wire, using it as a guide. There is no need to cut the wire in the MIG gun. The QUICK LOAD liners for 0.078” to 3/32” wire require the new 415-24 QUICK LOAD liner retainer, while all other liner sizes use Tregaskiss’ existing 415-26 retainer. Tregaskiss offers QUICK LOAD liners in lengths up to 25 feet for Bernard® T-Gun™ semi-automatic MIG guns (formerly Tregaskiss® TOUGH GUN® semi-automatic MIG guns) and up to 15 feet long for robotic applications. On semi-automatic applications, the liners can be easily changed even when the MIG gun is mounted to feeders on booms; there is no need to climb up to the feeder. Similarly, on robotic applications, the QUICK LOAD liner minimizes downtime by eliminating the trouble of maneuvering around tooling or transferring systems to remove the MIG gun from the wire feeder. It also allows for liner changeover from a safe-zone outside the work cell during routine pauses in production. The QUICK LOAD liners are particularly beneficial when coupled with Tregaskiss’ TOUGH GUN ThruArm® series robotic MIG guns, as the wire feeders in through-arm systems are closely positioned next to the robot’s casting and can be cumbersome to move during conventional liner changeover.

November 12, 2010 Effective Monday, November 12, 2010, Tregaskiss has released a new design for the TOUGH GUN® reamer cutter blades. The new product is made in North America and has passed a series of stringent tests. As a result, we are proud to implement this product, approved by the Tregaskiss Engineering team, as our new standard offering. The new design will be implemented as a ‘running change’ and will be sold under the same part numbers as the previous design.

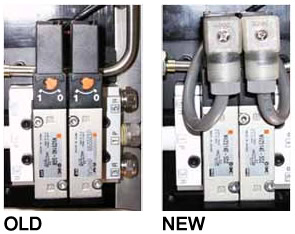

May 7, 2008 Previously we have supplied the type of TR-2210 solenoid valves (made by SMC) for the TOUGH GUN® reamer as shown in the image on the left (OLD). We now offer an improved DIN connection for this product (also from SMC) shown in the image on the right (NEW). This new product is rated “IP65” (as defined in international standard IEC 60529), where: NOTE: This product is designed for use ONLY on TOUGH GUN reamers with externally mounted valves. Refer to product insert INS053 for more information about TR-2210 solenoid valves for TOUGH GUN reamers with external valves.

August 21, 2008 The TOUGH GUN® sprayer, used as a stand-alone unit or on a TOUGH GUN reamer, has been improved in the following ways: Refer to product insert INS058 for more information about RR-1320 anti-spatter reservoirs for TOUGH GUN reamers.

May 14, 2008 The design of the wire cutter blade has been improved to more securely fasten to the TOUGH GUN® wire cutter (WC-100). The WC-100-7 wire cutter blade kit includes the new blade and insert, and is backwards compatible with older wire cutters. Product insert INS049 provides installation and replacement instructions. Factory-installed wire cutter features a built-in heli-coil and use a “socket-counter-sunk-head cap screw” (SCHCS) or flat-head screw to fasten the blade to the wire cutter.

March 2, 2008 The next generation TOUGH GUN® reamer will knock you out with its powerful one-two punch: Rugged durability PLUS new features that improve reliability, ease maintenance, and provide a safer and more accurate setup. Watch our online animation to learn more about the Next Generation TOUGH GUN reamer from Tregaskiss.

June 24, 2009 Tregaskiss has implemented a series of changes to the TOUGH GUN® robotic neck checking fixtures product line. Below is the new simplified offering of robotic neck checking fixtures: *Base plate not included, but the drawings are available free of charge from the Tregaskiss Technical Services department. For more information, please refer to the M042 technical product manual for TOUGH GUN robotic neck checking fixtures.

June 19, 2008 Tregaskiss is proud to introduce the TOUGH GUN® ThruArm® series featuring low-stress robotic (LSR) unicable technology. This new robotic MIG gun feeds through the arm of the robot and incorporates a unique unicable that offers 360 degrees of continuous rotation. Designed specifically to minimize downtime and improve welding performance on today’s through-arm robotic welding systems, the TOUGH GUN ThruArm series with LSR unicable technology is available as a complete package (from the feeder to the contact tip) for both clutch and solid mount robotic systems, including those by FANUC®, OTC Daihen®, ABB® and Motoman®. Click here to learn more about this product.

December 8, 2008 Tregaskiss is pleased to offer an improved rear housing for robotic Euro MIG guns (part #677E), which provides improved protection from the welding environment, it’s easier to install and maintain, it has a larger, more robust spring, and it’s backwards compatible with existing robotic Euro MIG guns.

October 1, 2008 As of October 1, 2008, the 450 amp TOUGH GUN® robotic water-cooled MIG gun models have been replaced with 550 amp MIG Guns equipped with TOUGH GUN I.C.E.® technology. Replacement parts and consumables for existing 450 amp robotic water-cooled MIG guns will continue to be sold by Tregaskiss for a period of 5 years*. *Availability and list prices of replacement parts for the affected products are subject to change without notice. Click here for more information.

March 25, 2008 Tregaskiss has discontinued the AS-708-22 (6′) and AS-708-23 (12′) control cables and replaced them with Coupled with the AS-708-14-1 “curly” clutch cord (with LED lights), the new AS-708-2406 (6′) and AS-708-2412 (12′) control cables should experience improved longevity and performance compared to the old cords.

December 16, 2010 As of December 31, 2010, the Tregaskiss® 600 amp robotic water-cooled MIG gun will replace the 650 amp robotic water-cooled MIG gun. Click here for more information.

November 2, 2010 To maximize productivity when welding thick plate and/or operating for prolonged duty cycles, Tregaskiss offers its robotic water-cooled MIG gun, which includes a new wire brake feature. The wire brake feature works in conjunction with wire touch sensing to help determine the location of weld joints and supports good weld quality and productivity. This feature can be ordered through Tregaskiss’ MIG gun Configurator and is available for wire sizes from 0.035- to 1/16-inch diameter. The Tregaskiss® robotic water-cooled MIG gun also includes a high-flow neck with four cooling channels and a water-cooled power cable that provides excellent cooling capacity to the front-end consumables to help extend their service life and allow for longer periods of welding. Additionally, the TOUGH GUN robotic water-cooled MIG gun features a sturdy stainless steel docking body capable of withstanding the harsh environments common to high-amperage welding applications, along with a durable conduit that swivels independently to provide rigid support for the liner, ensure smooth and consistent wire feeding, and minimize downtime for maintenance. Adding to the ease of maintenance, the new MIG gun has an accessible front housing, quick-change fittings and replaceable components, all features that support greater productivity by lessening the time needed to care for the gun. The Tregaskiss robotic water-cooled MIG gun uses the TOUGH LOCK® consumable platform — common across Tregaskiss robotic and automatic MIG guns and Bernard® T-Gun series (formerly Tregaskiss TOUGH GUN semi-automatic MIG guns) and TGX® series (formerly Tregaskiss TGX series) MIG guns, allowing users of multiple styles of guns to simplify and reduce their overall inventory of welding consumables. This robotic MIG gun provides 600 amps welding capacity at 100 percent duty cycle with CO2 shielding gas or 60 percent duty cycle when welding with mixed gases. Further, Tregaskiss R&D testing and extensive field trials have proven this MIG gun is a reliable performer in the most demanding welding applications, including thick-plate welding that is common in the heavy-equipment manufacturing industry. This robotic MIG gun represents the future of the TOUGH GUN robotic water-cooled product line and, as of December 31, 2010 it has completely replaced Tregaskiss’ existing TOUGH GUN quick-change water-cooled (QCWC) and keyed water-cooled (KWC) robotic MIG guns.

PRODUCT IMPROVEMENT – Quick-Connect Blocks

PRODUCT IMPROVEMENT —

Quick-Connect Blocks

Affected Part Numbers and Descriptions

PRODUCT CHANGE – Tregaskiss Bags and Roll Marks

PACKAGING IMPROVEMENT —

Changes to Tregaskiss Bags and Roll Marks

PRODUCT UPDATE – New QUICK LOAD Liner Wire Sizes

PRODUCT UPDATE —

Expanded QUICK LOAD Liner Product Offering

PRODUCT IMPROVEMENT – Reamer Cutter Blades

PRODUCT IMPROVEMENT —

TOUGH GUN Reamer Cutter BladesSummary of Design Changes

PRODUCT IMPROVEMENT – Solenoid Valve for TOUGH GUN Reamer Robotic Nozzle Cleaning Stations

PRODUCT IMPROVEMENT —

Solenoid Valve for TOUGH GUN Reamers with External Valves

PRODUCT IMPROVEMENT – TOUGH GUN Sprayer

PRODUCT IMPROVEMENT —

TOUGH GUN Sprayer

PRODUCT IMPROVEMENT – Wire Cutter Blades

PRODUCT IMPROVEMENT —

Wire Cutter BladesNEW PRODUCT – Next Generation TOUGH GUN Reamer

NEW PRODUCT —

Next Generation TOUGH GUN Reamer

The TOUGH GUN Reamer just got TOUGHER!

PRODUCT UPDATE – Neck Checking Fixtures

PRODUCT UPDATE —

TOUGH GUN Neck Checking FixturesProduct Type Part Number Replaces Quick-Change Robotic Air-Cooled Necks G-405CA N/A TOUGH GUN I.C.E.® Robotic Necks G-405CA and G-495-8 G-4051 TOUGH GUN I.C.E. Robotic Necks with Wire Brake (WB) GS-105* G-405W Robotic Quick Change Water-Cooled (QCWC) Necks GS-103* G-495 Robotic Keyed Water-Cooled (KWC) Necks N/A G-458 NEW PRODUCT – TOUGH GUN ThruArm Series

NEW PRODUCT —

TOUGH GUN ThruArm Series Robotic MIG Guns

PRODUCT IMPROVEMENT – Rear Housing Design for Robotic Euro MIG Guns

PRODUCT IMPROVEMENT —

Rear Housing Design for Robotic Euro MIG Guns

DISCONTINUED PRODUCT – 450 amp Robotic Water-Cooled MIG Guns

DISCONTINUED PRODUCT — 450 amp TOUGH GUN Robotic Water-Cooled MIG Guns

Affected Products

PRODUCT IMPROVEMENT – Robotic External Control Cables

PRODUCT IMPROVEMENT —

Robotic External Control Cables

improved cord sets. The new cables are made from our existing AS-708-14-2 (straight clutch cord) and the Lumberg Micro-Connector (AS-708-22-2).

DISCONTINUED PRODUCT – Keyed and Quick-Change Water-Cooled MIG Guns

DISCONTINUED PRODUCT — TOUGH GUN Keyed and Quick-Change Water-Cooled MIG Guns

PRODUCT UPDATE – Robotic Water-Cooled MIG Gun Maximizes Productivity

PRODUCT UPDATE —

Tregaskiss Robotic Water-Cooled MIG Guns